Science Daily September 14, 2023

Hydrogen gas is the primary storable fuel for pollution-free energy production, with over 90 million tonnes used globally per year. More than 95% of H2 is synthesized through metal-catalyzed steam methane reforming that produces 11 tonnes of CO2 per tonne H2. “Green H2” from water electrolysis using renewable energy evolves no CO2, but costs 2–3x more, making it presently economically unviable. Researchers at Rice University have demonstrated catalyst-free conversion of waste plastic into clean H2 along with high purity graphene. The scalable procedure evolved no CO2 when deconstructing polyolefins and produces H2 in purities up to 94% at high mass yields. Sale of graphene byproduct at just 5% of its current value yields H2 production at negative cost. Life-cycle assessment demonstrated a 39–84% reduction in emissions compared to other H2 production methods, suggesting the flash H2 process is an economically viable, clean H2 production route… read more. TECHNICAL ARTICLE (accepted for publication)

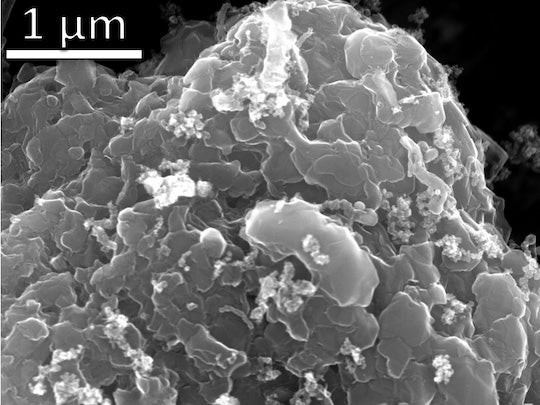

SEM image of layered stacks of nano-scale flash graphene sheets formed from waste plastic. Credit: Kevin Wyss/Tour lab, Rice University.