Science Daily December 21, 2022

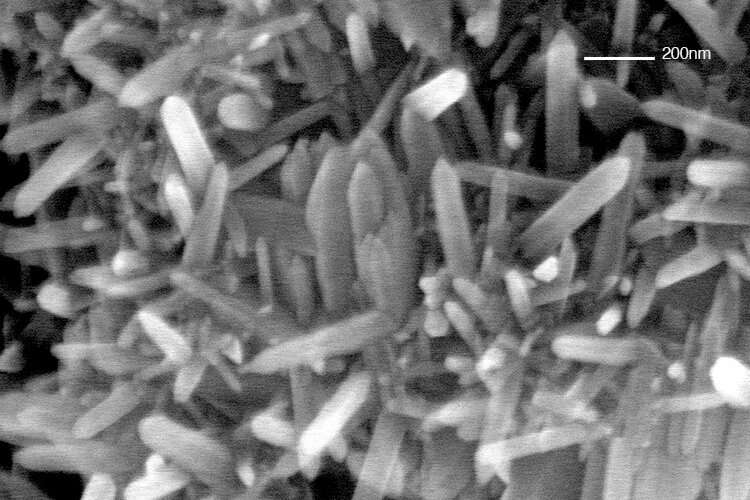

Researchers in Japan developed a cheap and simple process to create nanoscale structures on the surface of galvanized steel, which is commonly used in the automotive industry, that provided a more conducive interface for attaching injection-molded polymers. They used hot water treatment (HWT) to produce a nanoscale needle-like structure on the zinc coating surface to enhance the joining strength and obtained strong joints of galvanized high-strength steel (GHSS) and polybutylene terephthalate (PBT) with minimal damage to the zinc coating. The effects of HWT conditions on the tensile shear strength were evaluated and the optimized strength reached 23 MPa. The number of structure peaks (Np) showed a strong positive correlation with the joining strength. Mechanical interlocking was the essential reason for the high joining strength. The results proved the feasibility of the proposed strategy and its potential for practical application. This method may lead to lower-cost industrial production of lightweight and durable polymer-metal composite materials…read more. TECHNICAL ARTICLE

…a material ubiquitous in the automobile industry, to cheaply and easily create a lightweight and durable product. Credit: Institute of Industrial Science, The University of Tokyo