Nanowerk June 7, 2021

Currently, carbon-based overcoats (COCs), layers used to protect platters from mechanical damages and corrosion, occupy a significant part of this spacing. An international team of researchers (India, Singapore, UK, USA – Argonne National Laboratory, University of Illinois, Switzerland) replaced commercial COCs with one to four layers of graphene which fulfills all the ideal properties of an HDD overcoat in terms of corrosion protection, low friction, wear resistance, hardness, lubricant compatibility, and surface smoothness. They transferred graphene onto hard disks made of iron-platinum as the magnetic recording layer, and tested Heat-Assisted Magnetic Recording (HAMR) that enables an increase in storage density by heating the recording layer to high temperatures. They have shown a jump in HDDs’ data density by a factor of ten and a significant reduction in wear rate critical to achieving more sustainable and durable magnetic data recording. The work demonstrates that graphene can serve as protective coating for conventional h, and disk drives and that it is able to withstand HAMR conditions further pushing the development of novel high areal density hard disk drives…read more. Open Access TECHNICAL ARTICLE

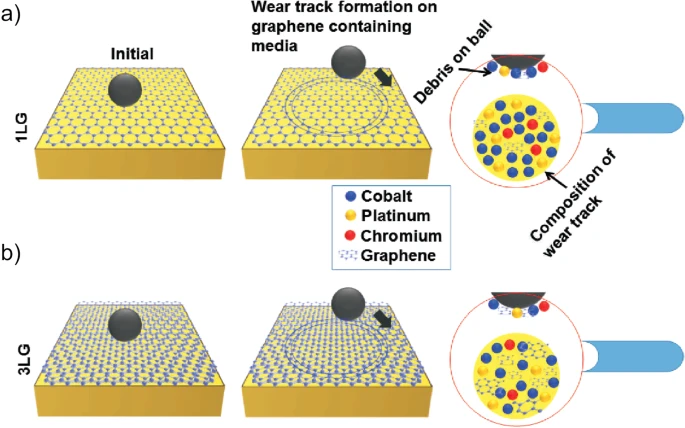

Friction model. Credit: Nature Communications volume 12, Article number: 2854 (2021)