Science Daily May 3, 2023

About 90% of the acetic acid market is for feedstock in the manufacture of paints, coatings, adhesives, and other products. Production at this scale is primarily derived from methanol, which comes from fossil fuels. An international team of researchers (China, Canada, New Zealand, USA – Northwestern University) has created acetic acid out of carbon monoxide derived from captured carbon. Their process consisted of capturing CO2 and passing it through an electrolyzer where it reacted with water and electrons to form carbon monoxide. Gaseous CO was then passed through a second electrolyzer, where another catalyst transformed it into various molecules containing two or more carbon atoms. Most of the catalysts used for this second step facilitated multiple simultaneous reactions, which led to a mix of different two-carbon products that could be hard to separate and purify. They set up conditions that favored one product above all others. The team’s analysis showed that using a much lower proportion of copper (approximately 1%) compared with previous catalysts would favor the production of just acetic acid. It also showed that elevating the pressure to 10 atmospheres would enable the team to achieve record-breaking efficiency. According to the researchers their work provides new pathways to improve economics, and a more sustainable source for the industrial chemicals that we need… read more. TECHNICAL ARTICLE

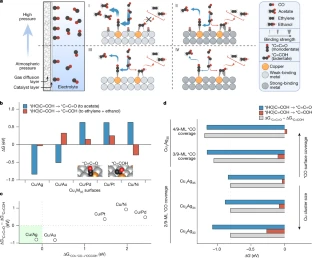

CO-to-acetate electrocatalyst design. Credit: Nature (2023)