Phys.org September 2, 2022

An international team of researchers (Russia, USA – University of Notre Dame) has developed a new simplified method of producing industrial cobalt-nickel catalysts for carbon dioxide processing that makes the process simple and inexpensive. The catalysts are a bulk alloy with a porous surface and nanoscale grains that form foamy high-activity particles. Due to the structure and the synergistic interaction of Co with Ni, the catalysts are characterized by a more intense interaction with CO2 molecules and high stability. They focused on exploring the possibilities of full utilization of carbon dioxide, simplifying the production of effective catalysts, and creating catalysts based on available raw materials. A small amount of energy is applied to heat a sample volume, up to one cubic millimeter, and the synthesis proceeds in a self-sustaining mode without additional energy costs. According to the researchers cobalt contributes to the formation of a porous sponge-like microstructure of the catalyst and triples the catalytic properties of nickel. The catalyst has a much higher thermal conductivity which significantly increases the stability of the material during long-term use. The use of non-standard synthesis methods has significantly reduced energy and resource costs in the production and use of the catalysts. According to the scientists, the valuable products of this reaction can be the synthesis gas, various hydrocarbons and alcohols widely used in the chemical industry…read more. Open Access TECHNICAL ARTICLE

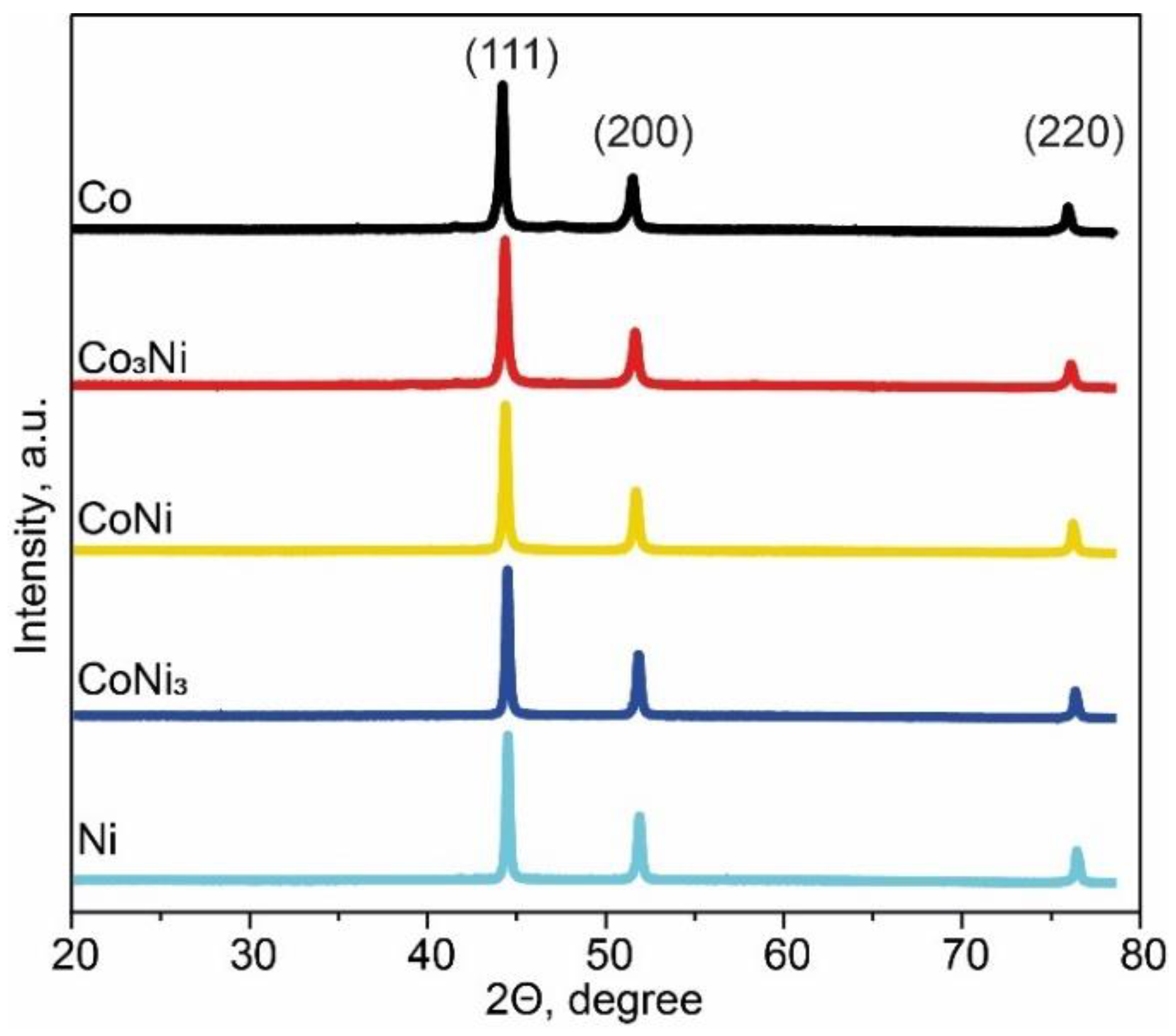

XRD patterns of the catalyst powders synthesized by SGCS. Credit: Materials 2022, 15(15), 5129