Phys.org August 4, 2022

Water droplets must have large apparent contact angle (CA) (>150°) and small CA hysteresis (<10°) on hydrophobic surfaces. Previous research usually involved complex fabrication strategies to modify the surface wettability. Researchers at Rice University developed a simple technique that involves sandpaper and a selection of powders which are sanded into the surface. They applied the technique on a variety of surfaces (Teflon, polyethylene, polypropylene, polystyrene, polyvinyl chloride, and polydimethylsiloxane) with a variety of powder additives. These included laser-induced graphene fiber, turbostratic flash graphene, molybdenum disulfide, Teflon, and boron nitride. A variety of aluminum oxide sandpapers were used, from 180- to 2,000-grit. In demonstrations the resistant materials were robust after heating to 130 degrees Celsius, even after months of exposure to the elements, re-sanding them could refresh their hydrophobicity. They discovered that by changing the sand-in conditions and the powder additives, materials can also be made hydrophilic… read more. TECHNICAL ARTICLE

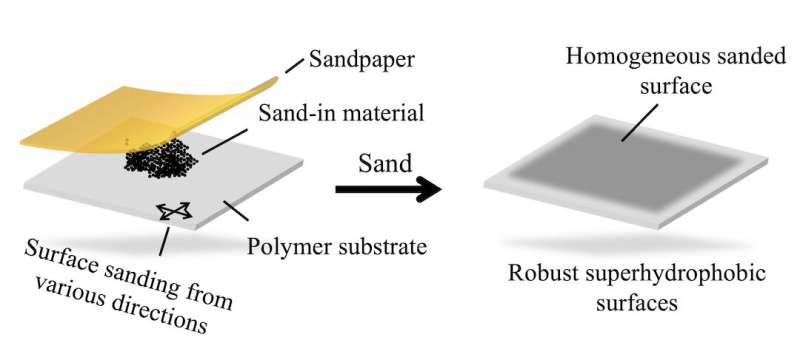

An illustration shows the sand-in technique developed at Rice to make materials superhydrophobic. The one-step method involving sandpaper and powder also gives materials enhanced anti-icing properties. Credit: ACS Appl. Mater. Interfaces 2022, 14, 30, 35053–35063, July 21, 2022