MIT News February 10, 2022

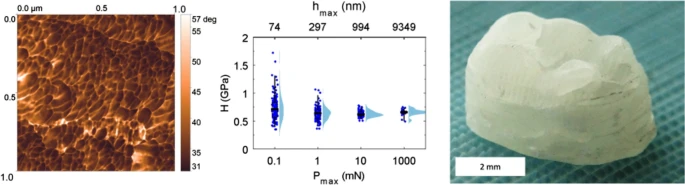

So far researchers have been able to incorporate low fractions of the exceptionally strong carbon nanocrystals (CNCs), as the crystals tend to clump and only weakly bond with polymer molecules. To develop a composite with a high fraction of CNCs researcher at MIT determined the ratio of CNC and polymer that would turn the solution into a gel, with a consistency that could either be fed through the nozzle of a 3-D printer or poured into a mold to be cast. When dried the material shrank, leaving behind a solid composite composed mainly of cellulose nanocrystals. They tested it for strength and hardness. The composite had zig-zag microstructure which stops a crack from running straight through the material. In tests across multiple scales, the composite’s arrangement of cellulose grains prevented the cracks from splitting the material. This resistance to plastic deformation gives the composite a hardness and stiffness at the boundary between conventional plastics and metals. The formulation, processing route, and insights on toughening mechanisms gained from their multiscale approach can be applied broadly to highly loaded nanocomposites….read more. TECHNICAL ARTICLE

Graphical abstract. Credit: Cellulose (2022)