Phys.org October 22, 2021

An international team of researchers (USA – Rice University, South Dakota School of Mines and Technology, SUNY Buffalo, George Washington University, Rensselaer Polytechnic Institute, Canada) has designed a lightweight sulfur–selenium (S–Se) alloy with high stiffness and ductility that can serve as an excellent corrosion-resistant coating with protection efficiency of ≈99.9% for steel in a wide range of diverse environments. S–Se coated mild steel showed a corrosion rate that is 6–7 orders of magnitude lower than bare metal in abiotic (simulated seawater and sodium sulfate solution) and biotic (sulfate-reducing bacterial medium) environments. The coating is strongly adhesive, mechanically robust, and demonstrated excellent damage/deformation recovery properties. The high corrosion resistance of the alloy in diverse environments is attributed to its semicrystalline, nonporous, antimicrobial, and viscoelastic nature with superior mechanical performance, enabling it to successfully block a variety of diffusing species…read more. TECHNICAL ARTICLE

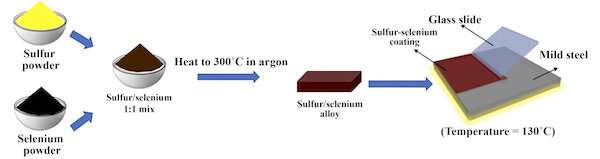

An illustration shows the simple process of combining powdered sulfur and selenium into a compound able to protect mild steel from the elements. Credit: Ajayan Research Group