Phys.org June 17, 2024

Widespread use of titanium is significantly hampered by its strong affinity to oxygen, resulting in elevated manufacturing costs during the refining, melting, and casting processes. Researchers in Japan introduced a high-throughput technique, that effectively reduced the oxygen content in molten titanium to a level suitable for structural material applications, to streamline the mass production of titanium by seamlessly integrating the refining, melting, and casting processes. The process leveraged the high affinity of rare-earth metals, such as yttrium (Y), for oxygen. They utilized the formation reaction of their oxyhalides (YOF) to directly remove oxygen from liquid titanium which resulted in titanium with a significantly reduced oxygen content of 200 mass ppm. The technique enabled direct conversion of titanium oxide feeds into low-oxygen titanium without requiring conversion into intermediate compounds. The process offers a pathway for the upgrade recycling of high-oxygen-content titanium scrap directly into low-oxygen titanium and lowers titanium production costs… read more. Open Access TECHNICAL ARTICLE

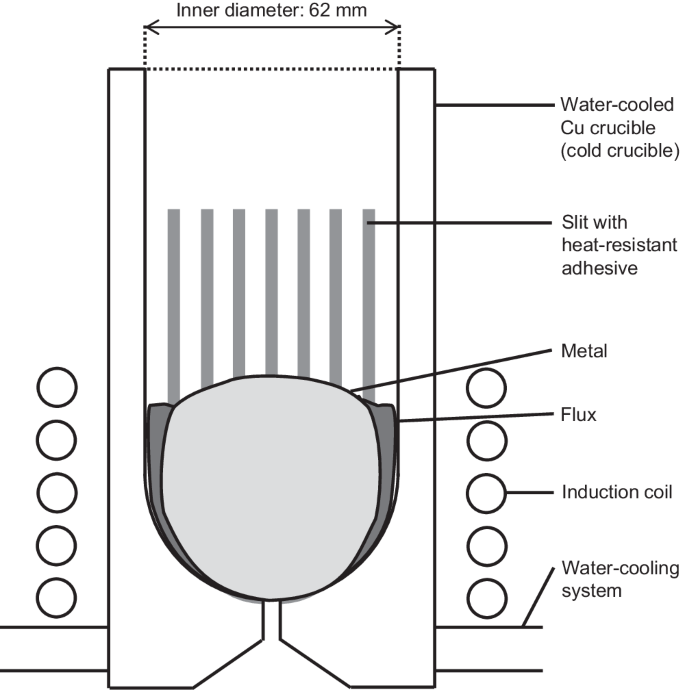

Schematic diagram (cross-sectional view) of experimental apparatus for melting … Credit: Nature Communications volume 15, Article number: 5015 (2024)