Phys.org November 6, 2023

Existing terahertz inspection systems face throughput and accuracy restrictions due to their limited imaging speed and resolution. Furthermore, machine-vision-based systems using large-pixel-count imaging encounter bottlenecks due to their data storage, transmission, and processing requirements.

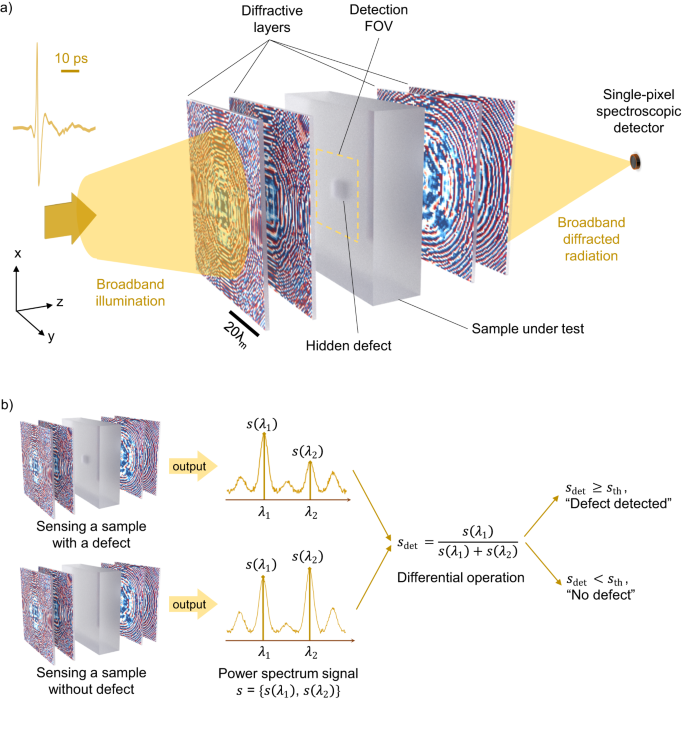

Researchers at UCLA developed a diffractive sensor that rapidly detects hidden defects/objects within a 3D sample using a single-pixel terahertz detector, eliminating sample scanning or image formation/processing. Using deep-learning-optimized diffractive layers, the diffractive sensor could all-optically probe the 3D structural information of samples by outputting a spectrum, and directly indicated the presence/absence of hidden structures or defects. They experimentally validated this framework using a single-pixel terahertz time-domain spectroscopy set-up and 3D-printed diffractive layers, and successfully detected unknown hidden defects inside silicon samples. According to the researchers this technique is valuable for applications including security screening, biomedical sensing, and industrial quality control… read more. Open Access TECHNICAL ARTICLE

Schematic of a diffractive terahertz sensor… Credit: Nature Communications volume 14, Article number: 6791 (2023)