Phys.org February 9, 2023

Low-temperature decomposition of supersaturated solid solution into unfavorable intergranular precipitates is a long-standing bottleneck limiting the practical applications of nanograined aluminum alloys that are prepared by severe plastic deformation. Minimizing the vacancy concentration is generally regarded as an effective approach in suppressing the decomposition process. An international team of researchers (China, Norway, Italy) has developed a strategy to stabilize supersaturated solid solution in nanograined Al-Cu alloys via high-density vacancies in combination with Sc microalloying. By generating a two orders of magnitude higher concentration of vacancies bonded in strong (Cu, Sc, vacancy)-rich atomic complexes, a high thermal stability is achieved in an Al-Cu-Sc alloy that precipitation was nearly suppressed up to ~230 °C. The solute-vacancy complexes also enabled the nanograined Al-Cu alloys with higher strength, greater strain hardening capability and ductility. According to the researchers their findings provide perspectives towards the great potentials of solute-vacancy interaction and the development of nanograined alloys with high stability and well-performed mechanical properties… read more. Open Access TECHNICAL ARTICLE

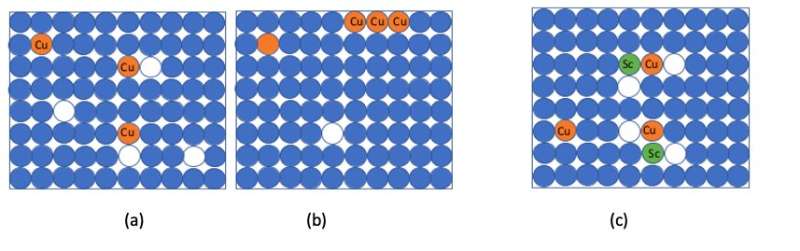

Copper atoms alone can easily move through the material by exchanging positions with vacancies as shown… Credit: Nature Communications volume 13, Article number: 3495 (2022)